| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Saibo

Model Number : C-Z

Certification : CE/ISO

Place of Origin : China

MOQ : 1 set

Price : negotiation

Supply Ability : 300 sets per year

Delivery Time : 90 days

Packaging Details : Suitable for ocean shipment

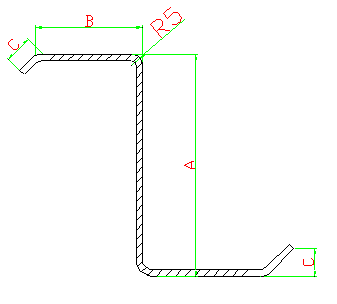

Product Name : High Speed C Z Purlin Roll Forming Machine

Shaft diameter : 70mm soild shaft

Decoiler : Hydraulic or manual

Station : About 15 stations

Roller material : Gcr15

Cutting system : Track cutting system

Speed : 25-30m/min

Total power : 75kw

High Speed C Z Purlin Roll Forming Machine ¢70mm solid shaft By Gear Box

1. Main speficication:

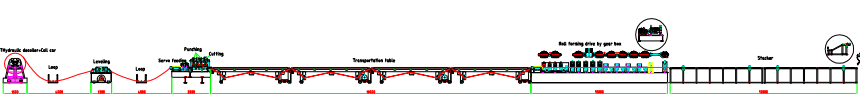

2.The Chart of Process Flow

5T hydraulic single head Uncoiler+ Coil car—Feeding& Leveling—Servo feeding &hydraulic punching(3stations)&Cutting—Feeding& transportation table—Roll Forming—Rectify—Auto stacker

3.Specification of Components

| No | Technical Specification & Remark | |

| 1 | 5T hydraulic uncoiler with coil car

|

|

| 2 | Leveling part

|

|

| 3 | Servo feeding& Punching&Cutting

|

|

| 4 | Transportation table

|

|

| 5 | Main Roll Forming Machine

|

|

| 6 | Correction adjust system

|

|

| 7 | Hydraulic System

|

|

| 8 | Computer Control Cabinet

|

|

| 9 | Stacker

|

|

| 10 | Spare Parts

|

|

4. Warranty

1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of shipment. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 100$ per day shall be for purchaser’s account if manufacturer’s engineer has to be send to purchaser’s factory to maintain the machine during the guarantee period.

5. FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

6) Q: Do you have this roof panel roll forming machine in stock?

A: No, machine is made to order.

|

|

High Speed C Z Purlin Roll Forming Machine with 70mm soild shaft Images |